Key Takeaways

- Corten steel is known for its weathering properties, providing exceptional durability to shipping containers.

- Standard sizes for shipping containers typically include 20-foot and 40-foot lengths, with custom sizes available.

- These containers are used not only for transport but also for storage, construction, and even as building blocks for homes and offices.

- Benefits of using Corten steel include its strength, longevity, and maintenance-free nature once the protective rust layer has formed.

- Properly maintained, a Corten steel container can last for decades, even in harsh environmental conditions.

Corten Steel: The Heart of Durable Shipping Container Architecture

At the core of every shipping container is Corten steel, also known as weathering steel. This special alloy includes elements like copper, chromium, and nickel, which give it a unique ability to resist corrosion. When exposed to the elements, it develops a rust-like appearance that actually protects the steel from further deterioration. This is why containers made from Cortin steel are so durable and can last for years without needing paint or other protective coatings.

Most importantly, the containers are designed to be both modular and strong. They can be stacked high, withstand the weight of heavy cargo, and survive the rigors of ocean travel. Because of these properties, Corten steel containers have become a staple in the shipping industry and beyond.

My Favorite Container Homes Resource

I compared the top 3 Container Home Guides

to discover the ultimate resource!

See my top recommendation here

The Science Behind Corten Steel Durability

The magic of Corten steel lies in its chemical composition. When exposed to the elements, the steel forms a protective layer of rust that shields the deeper layers from corrosion. This patina develops under the influence of the weather and doesn’t require any additional treatment or paint, which makes it environmentally friendly and cost-effective.

Why Corten Steel is a Game-Changer for Eco-Conscious Builders

Besides its durability, Corten steel is a favorite among eco-conscious builders. Its longevity means that it doesn’t need to be replaced as often as other materials, reducing waste. Additionally, shipping containers are often retired from service after a certain number of years, and Corten steel’s sturdiness makes these containers perfect for repurposing into buildings, reducing the demand for new construction materials.

Therefore, Corten steel isn’t just tough; it’s a sustainable choice that supports a circular economy.

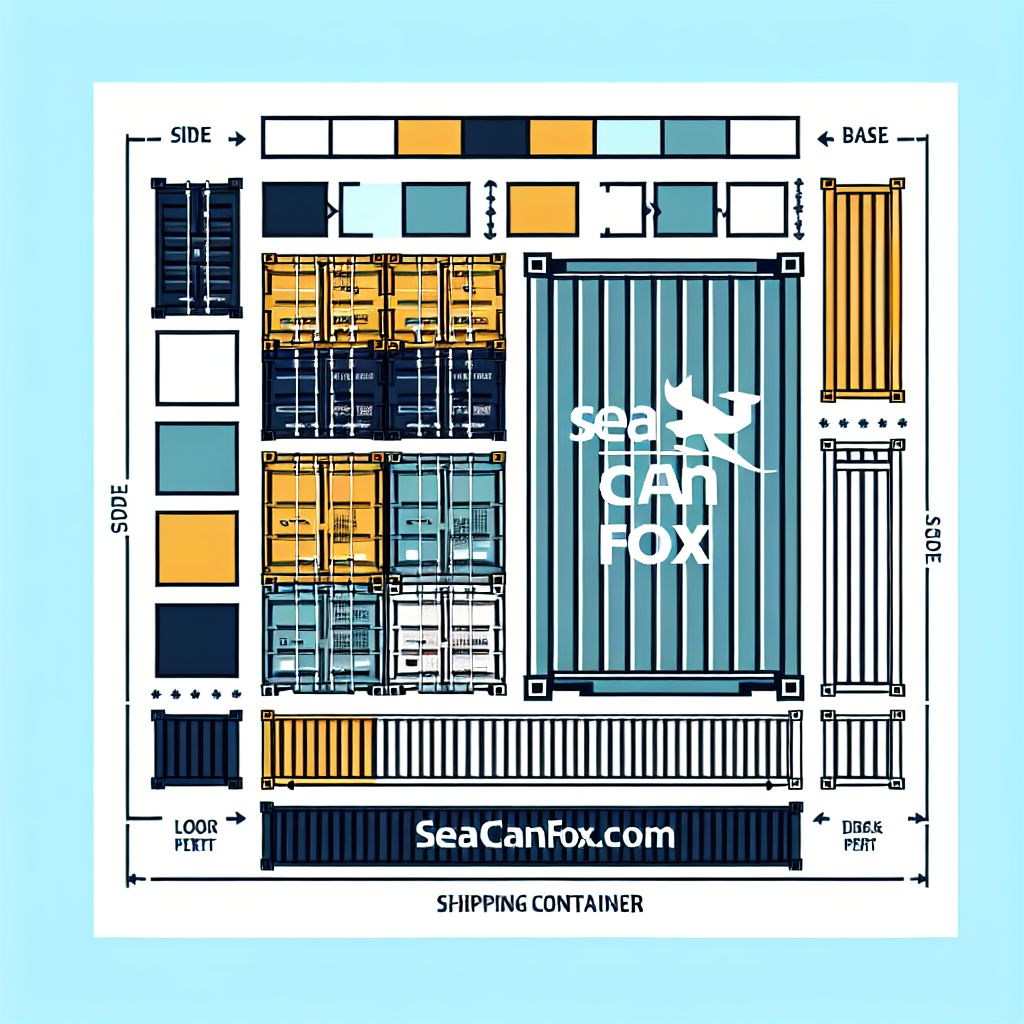

Designing with Corten: The Blueprint of Sustainable Shipping Containers

Designing a shipping container starts with understanding the unique properties of Corten steel and how to work with them. The blueprint of a shipping container is quite simple: a rectangular box made to withstand immense pressure, heavy loads, and extreme weather. However, the simplicity of the design belies the complexity of the engineering involved.

Blueprint Basics: From Sketch to Steel

The design process begins with a precise sketch that outlines the container’s dimensions, where the steel will be cut, and where the pieces will join together. These sketches serve as the roadmap for the manufacturing process, ensuring that each container meets the stringent standards required for international shipping.

Customization and Modification: Adapting to Purpose

While standard shipping containers come in 20-foot and 40-foot lengths, customization is possible to meet specific needs. This flexibility is one of the many reasons why Corten steel containers are so popular. They can be modified with windows, doors, and even entire walls that fold out, transforming them into mobile offices, pop-up shops, or cozy homes.

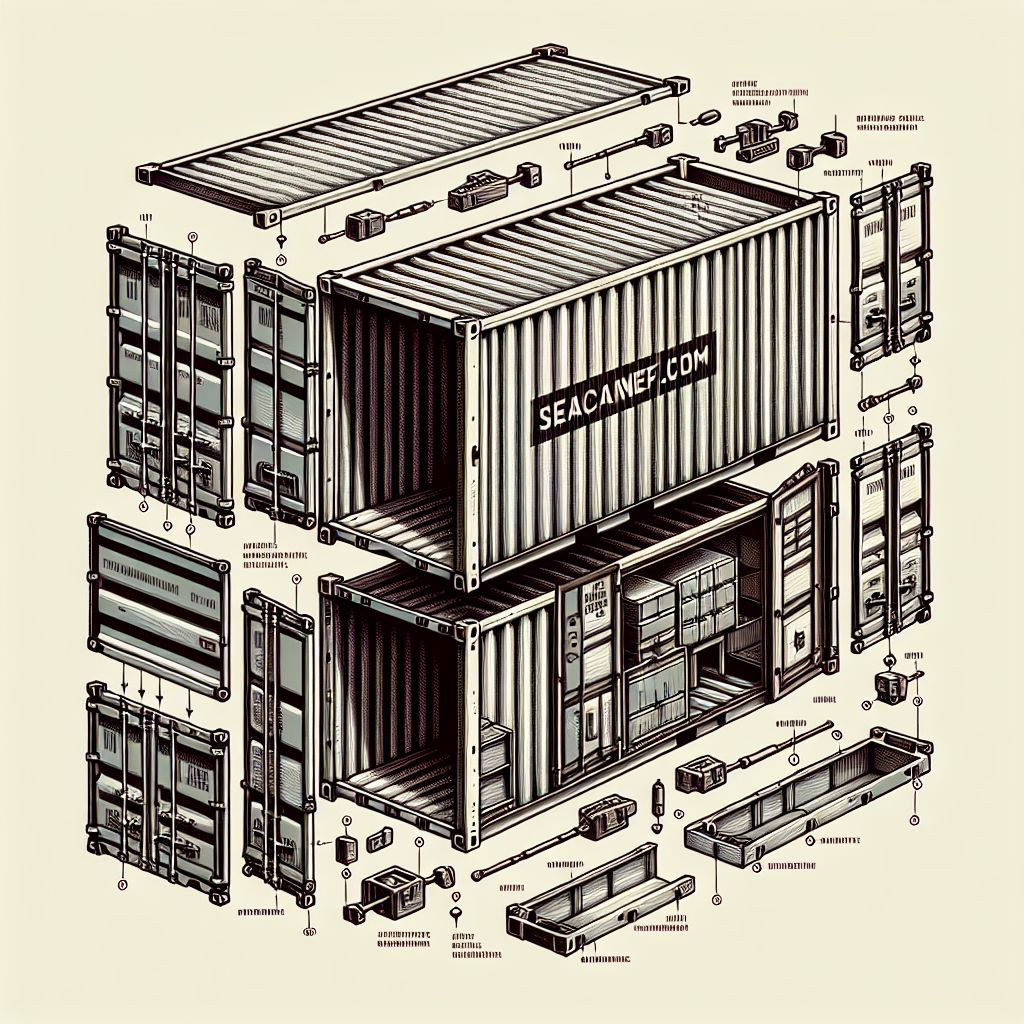

The Nuts and Bolts: Assembling a Corten Steel Container

The assembly of a Corten steel container is a marvel of modern manufacturing. Large sheets of steel are precision-cut, often by laser or plasma tools, to form the sides, roof, and floor of the container. The edges are then folded into shape and welded together to create a seamless structure that is both watertight and airtight.

Cutting and Joining: Techniques for Corten Steel Construction

When it comes to cutting and joining Corten steel for container construction, precision is key. High-definition plasma cutters slice through the steel with accuracy, ensuring that each piece fits together perfectly. The edges are then expertly welded, creating joints that are as strong as the steel itself. This meticulous process is crucial for maintaining the structural integrity of the container, especially when it’s destined to carry heavy loads across tumultuous seas.

Assembly Line Efficiency: Speed and Precision in Fabrication

Efficiency on the assembly line is paramount. Skilled workers and advanced machinery work in tandem, moving from station to station, each step carefully timed and executed. The result is a production line that can churn out a shipping container in a matter of hours. But speed doesn’t mean a compromise in quality; each container is rigorously inspected to ensure it meets the high standards expected of Corten steel construction.

From Factory Floor to Field: Logistics of Corten Container Deployment

Once a Corten steel container has been assembled, it’s ready to begin its journey. But getting from the factory floor to its final destination is no small feat. These hefty structures require specialized handling equipment and vehicles for transport. Trucks, trains, and even cargo ships are all part of the logistical ballet that moves containers around the globe.

Transport Considerations for Large Steel Structures

Moving large steel structures like shipping containers requires careful planning. Routes must be chosen to accommodate the size and weight of the loads, and the timing must be meticulously coordinated to avoid delays. It’s a complex puzzle that logistics experts solve daily to ensure that goods are moved efficiently and safely.

On-Site Setup: Ensuring Stability and Longevity

Once a shipping container reaches its destination, the setup is crucial for its stability and longevity. The ground must be level and firm, often requiring a foundation of concrete or gravel. The container is then placed using cranes or forklifts, and if multiple containers are being used together, they must be securely fastened to one another to prevent any movement.

Moreover, the container must be situated in a way that allows for easy access and, if necessary, connected to utilities. This careful placement ensures that the container can be used effectively for its intended purpose, whether that’s storage, transport, or as a building.

Repurposing Shipping Containers: Innovations in Corten Steel Design

The story of Corten steel containers doesn’t end with shipping goods. Their robust construction makes them ideal for repurposing into a variety of innovative designs. From trendy pop-up shops to cozy homes, the possibilities are nearly endless. And because Corten steel is so durable, these repurposed containers can last for many years with minimal maintenance.

Sustainable Living Spaces: Homes and Offices

One of the most popular uses for retired shipping containers is as sustainable living spaces. Architects and builders prize them for their strength, modularity, and unique aesthetic. With the addition of

Community Impact: Public Spaces and Emergency Shelters

Corten steel containers also make a significant impact in communities, particularly as public spaces and emergency shelters. Their ability to be quickly deployed and modified makes them an excellent choice for disaster relief housing, pop-up clinics, and community centers. These containers provide not just a practical solution but also a symbol of resilience and innovation.

Preserving Your Investment: Maintenance Tips for Corten Steel Containers

To maintain a Corten steel container, regular inspections are key. Look for any signs of damage, such as dents or scratches that could lead to rust. Keeping the container clean and free of debris also helps to prevent corrosion. And while the rust layer that forms on Corten steel is protective, any areas where the bare metal is exposed should be treated to prevent rust from spreading.

In conclusion, Corten steel shipping containers are a testament to the ingenuity of modern engineering. Their construction is a process that demands precision and expertise, resulting in structures that are not only functional but also sustainable. Whether they’re crossing oceans, sitting in a backyard, or housing a community center, these containers stand as a durable and versatile solution in a world that’s constantly moving and changing.

Imagine a material that not only stands up to the harshest weather conditions but also becomes stronger and more resilient as it weathers. That’s Corten steel for you, a revolutionary alloy that’s transforming the construction of shipping containers. These robust, Corten steel shipping containers, often referred to as sea conex boxes, are the unsung heroes of global trade, and their fabrication is a fascinating blend of science and skill.

Key Takeaways

- Corten steel is known for its weathering properties, providing exceptional durability to shipping containers.

- Standard sizes for shipping containers typically include 20-foot and 40-foot lengths, with custom sizes available.

- These containers are used not only for transport but also for storage, construction, and even as building blocks for homes and offices.

- Benefits of using Corten steel include its strength, longevity, and maintenance-free nature once the protective rust layer has formed.

- Properly maintained, a Corten steel container can last for decades, even in harsh environmental conditions.

Corten Steel: The Heart of Durable Shipping Container Architecture

At the core of every shipping container is Corten steel, also known as weathering steel. This special alloy includes elements like copper, chromium, and nickel, which give it a unique ability to resist corrosion. When exposed to the elements, it develops a rust-like appearance that actually protects the steel from further deterioration. This is why containers made from Cortin steel are so durable and can last for years without needing paint or other protective coatings.

Most importantly, the containers are designed to be both modular and strong. They can be stacked high, withstand the weight of heavy cargo, and survive the rigors of ocean travel. Because of these properties, Corten steel containers have become a staple in the shipping industry and beyond.

The Science Behind Corten Steel Durability

The magic of Corten steel lies in its chemical composition. When exposed to the elements, the steel forms a protective layer of rust that shields the deeper layers from corrosion. This patina develops under the influence of the weather and doesn’t require any additional treatment or paint, which makes it environmentally friendly and cost-effective.

Why Corten Steel is a Game-Changer for Eco-Conscious Builders

Besides its durability, Corten steel is a favorite among eco-conscious builders. Its longevity means that it doesn’t need to be replaced as often as other materials, reducing waste. Additionally, shipping containers are often retired from service after a certain number of years, and Corten steel’s sturdiness makes these containers perfect for repurposing into buildings, reducing the demand for new construction materials.

Therefore, Corten steel isn’t just tough; it’s a sustainable choice that supports a circular economy.

Designing with Corten: The Blueprint of Sustainable Shipping Containers

Designing a shipping container starts with understanding the unique properties of Corten steel and how to work with them. The blueprint of a shipping container is quite simple: a rectangular box made to withstand immense pressure, heavy loads, and extreme weather. However, the simplicity of the design belies the complexity of the engineering involved.

Blueprint Basics: From Sketch to Steel

The design process begins with a precise sketch that outlines the container’s dimensions, where the steel will be cut, and where the pieces will join together. These sketches serve as the roadmap for the manufacturing process, ensuring that each container meets the stringent standards required for international shipping.

Customization and Modification: Adapting to Purpose

While standard shipping containers come in 20-foot and 40-foot lengths, customization is possible to meet specific needs. This flexibility is one of the many reasons why Corten steel containers are so popular. They can be modified with windows, doors, and even entire walls that fold out, transforming them into mobile offices, pop-up shops, or cozy homes.

The Nuts and Bolts: Assembling a Corten Steel Container

The assembly of a Corten steel container is a marvel of modern manufacturing. Large sheets of steel are precision-cut, often by laser or plasma tools, to form the sides, roof, and floor of the container. The edges are then folded into shape and welded together to create a seamless structure that is both watertight and airtight.

Cutting and Joining: Techniques for Corten Steel Construction

When it comes to cutting and joining Corten steel for container construction, precision is key. High-definition plasma cutters slice through the steel with accuracy, ensuring that each piece fits together perfectly. The edges are then expertly welded, creating joints that are as strong as the steel itself. This meticulous process is crucial for maintaining the structural integrity of the container, especially when it’s destined to carry heavy loads across tumultuous seas.

Assembly Line Efficiency: Speed and Precision in Fabrication

Efficiency on the assembly line is paramount. Skilled workers and advanced machinery work in tandem, moving from station to station, each step carefully timed and executed. The result is a production line that can churn out a shipping container in a matter of hours. But speed doesn’t mean a compromise in quality; each container is rigorously inspected to ensure it meets the high standards expected of Corten steel construction.

From Factory Floor to Field: Logistics of Corten Container Deployment

Once a Corten steel container has been assembled, it’s ready to begin its journey. But getting from the factory floor to its final destination is no small feat. These hefty structures require specialized handling equipment and vehicles for transport. Trucks, trains, and even cargo ships are all part of the logistical ballet that moves containers around the globe.

Transport Considerations for Large Steel Structures

Moving large steel structures like shipping containers requires careful planning. Routes must be chosen to accommodate the size and weight of the loads, and the timing must be meticulously coordinated to avoid delays. It’s a complex puzzle that logistics experts solve daily to ensure that goods are moved efficiently and safely.

On-Site Setup: Ensuring Stability and Longevity

Once a shipping container reaches its destination, the setup is crucial for its stability and longevity. The ground must be level and firm, often requiring a foundation of concrete or gravel. The container is then placed using cranes or forklifts, and if multiple containers are being used together, they must be securely fastened to one another to prevent any movement.

Moreover, the container must be situated in a way that allows for easy access and, if necessary, connected to utilities. This careful placement ensures that the container can be used effectively for its intended purpose, whether that’s storage, transport, or as a building.

Frequently Asked Questions (FAQ)

What is Corten steel and why is it used for shipping containers?

Corten steel, also known as weathering steel, is an alloy that includes elements like copper, chromium, and nickel. This unique combination gives it exceptional durability and the ability to resist corrosion. When exposed to the elements, Corten steel forms a protective rust-like layer that prevents further deterioration, making it ideal for shipping containers that need to withstand harsh weather conditions.

Why are Corten steel containers popular among eco-conscious builders?

Corten steel containers are favored by eco-conscious builders because of their durability and sustainability. Their long lifespan means they don’t need to be replaced as often as other materials, reducing waste. Additionally, their robustness makes them perfect for repurposing into structures like homes and offices, minimizing the demand for new construction materials.

Can shipping containers be customized?

Yes, shipping containers can be customized to meet specific requirements. This flexibility allows for modifications such as adding windows, doors, and fold-out walls, transforming containers into mobile offices, pop-up shops, or homes. Custom sizes beyond the standard 20-foot and 40-foot lengths are also possible.

What are the logistics of transporting and deploying shipping containers?

Transporting large steel structures like shipping containers requires careful planning and specialized equipment. Routes are chosen to accommodate the size and weight of the containers, and timing is coordinated to avoid delays. Once at their destination, containers need to be placed on level, firm ground and, if used together, securely fastened to ensure stability and longevity.

What maintenance is required for Corten steel containers?

Regular inspections are essential to maintain a Corten steel container. Look for any damage, such as dents or scratches, that could lead to rust. Keeping the container clean and free of debris also helps prevent corrosion. Any exposed bare metal should be treated to stop rust from spreading, ensuring the container remains durable for years to come.

Leave a Reply