Key Takeaways

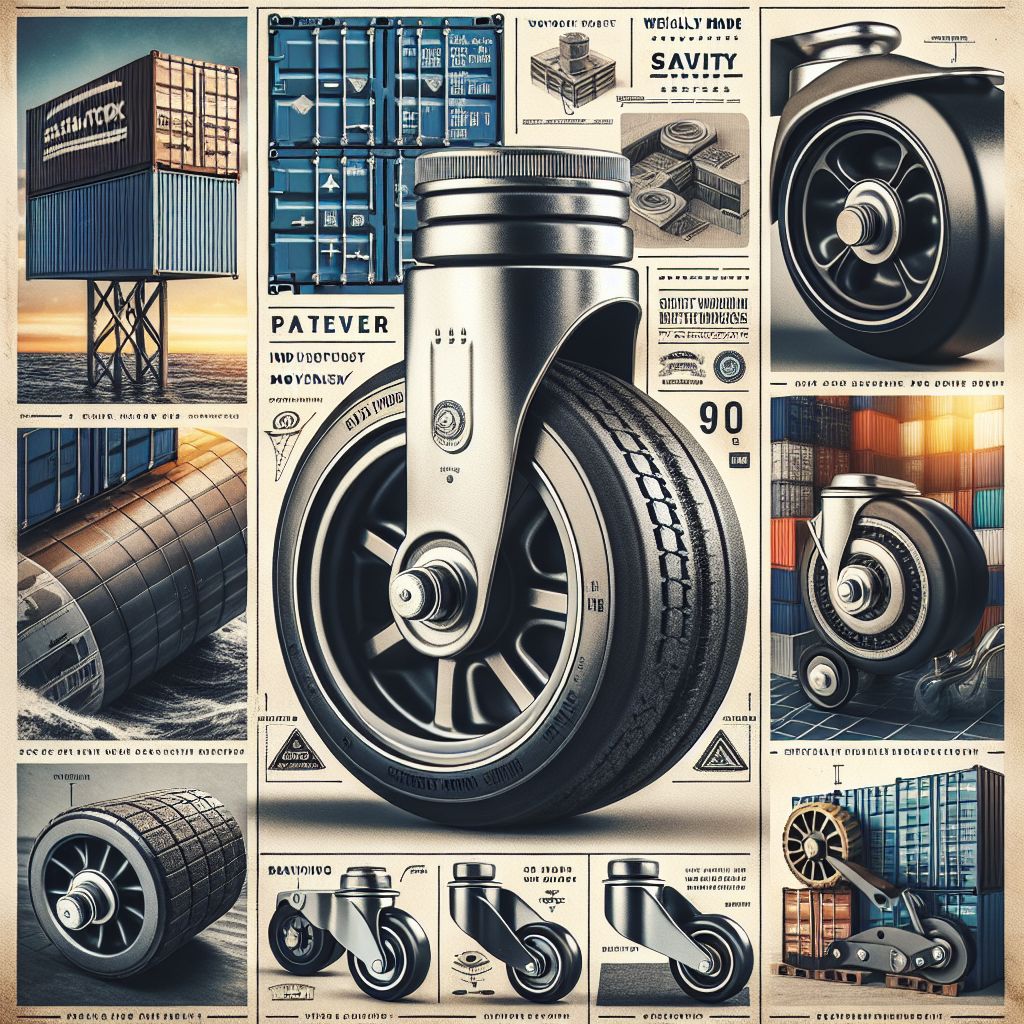

- Heavy-duty swivel casters are essential for moving shipping containers efficiently in many industrial settings.

- They come in various sizes and materials, each suitable for different uses and benefits.

- Proper selection based on load capacity, wheel material, and size can significantly improve maneuverability and reduce wear.

- Maintenance is crucial for longevity; routine checks ensure continuous performance.

- A well-chosen heavy-duty swivel caster can enhance operational efficiency and safety.

Why Your Industrial Setup Needs Heavy-Duty Swivel Casters

When it comes to handling heavy loads in an industrial setting, few components are as critical as the right set of wheels. Specifically, heavy-duty swivel casters for shipping containers can make or break your operational efficiency. These aren’t just any wheels; they’re the pivot point of mobility, enabling massive containers to glide across floors with ease.

Now, imagine a bustling warehouse. Every minute counts and the movement of goods can’t be a bottleneck. That’s where heavy-duty swivel casters come in, transforming static cargo into movable objects, streamlining workflows, and enhancing productivity. But not all casters are created equal. Selecting the right ones is paramount to your success.

My Favorite Container Homes Resource

I compared the top 3 Container Home Guides

to discover the ultimate resource!

See my top recommendation here

Let’s dive into the heart of the matter. Your industrial setup is like a complex organism, where every part must function seamlessly. In the world of material handling, heavy-duty swivel casters are the joints that offer both support and flexibility. They allow shipping containers to be positioned with precision, regardless of their heavy loads.

But why opt for heavy-duty swivel casters? Because when it comes to weight, standard casters just won’t cut it. These robust counterparts are built to withstand the immense pressure of industrial cargo, ensuring that your operations don’t just continue, but thrive under heavy demand.

The Game Changer for Material Handling

Think about the last time you had to push a heavy object. Now, imagine if that object could turn on a dime, responding to every subtle movement you make. That’s the game-changing advantage of swivel casters. They’re not just about moving forwards and backwards; they’re about agile, 360-degree movement that adapts to your space and needs.

Impact of Mobility on Shipping Efficiency

Mobility is more than a convenience; it’s a driver of efficiency. With heavy-duty swivel casters, you’re not just moving containers; you’re optimizing your entire shipping operation. Less time spent maneuvering means more time for the tasks that matter, and that’s a direct impact on your bottom line.

Most importantly, the right casters can reduce the physical strain on your team, leading to a safer workplace and fewer injury-related downtimes. Because when your team can move containers effortlessly, they can work smarter, not harder.

Rolling Out the Big Guns: Types of Heavy-Duty Swivel Casters

Before you can reap the benefits, you need to understand the types of heavy-duty swivel casters available. There are casters designed for smooth concrete floors, and those meant for the rugged terrain of a construction site. Some are non-marking, while others are built for high-temperature environments.

Comparing Wheel Materials and Surfaces

Wheel materials matter. Polyurethane wheels, for example, offer a balance between grip and durability, making them suitable for a variety of surfaces. Forged steel wheels, on the other hand, can handle extreme loads and resist wear, but they might not be the best choice for delicate flooring.

Diving into Load Capacities

Load capacity is a non-negotiable factor. It’s simple: if a caster can’t support the weight of your container, it’s not the right tool for the job. You need casters that can handle the load without buckling under pressure, ensuring safety and reliability.

Therefore, when choosing casters, always check their load rating and compare it with the weight of your containers. A good rule of thumb is to choose casters that can handle more than the maximum load you anticipate. This provides a safety buffer that can be crucial in preventing accidents.

The Mechanics Behind the Movement

Understanding the mechanics of swivel casters is essential. The swivel head allows the caster to rotate freely, which is what gives you that multidirectional movement. But it’s not just about the swivel; it’s about how smoothly it operates under load.

A swivel caster with a high-quality bearing system will turn more easily, reducing the force required to change direction. This is critical in tight spaces where precise movements are necessary.

And then there’s the mounting. The strength of the caster’s connection to the container is just as important as the wheel itself. A secure mount means no wobbling or detachment when you’re on the move.

In the next section, we’ll delve into the importance of size and how to select the right dimensions for your casters. After all, size isn’t just a number; it’s a key factor in performance and longevity.

Understanding Swivel Action for Maneuverability

Maneuverability is at the core of what makes heavy-duty swivel casters so valuable. These casters are designed to pivot smoothly, allowing shipping containers to be steered with ease. It’s the difference between a cumbersome push and a smooth glide.

The secret behind this ease of movement lies in the design of the swivel bearing. High-quality swivel bearings reduce friction, which in turn minimizes the effort needed to change directions. This is particularly important when navigating tight corners or repositioning containers in limited spaces.

The Lowdown on Locking Mechanisms

Now, while movement is good, control is equally important. This is where locking mechanisms come into play. Locking mechanisms on casters are akin to the brakes on a car; they halt movement when you need stability.

There are various locking options available, such as total locks, which stop both the wheel and swivel action, and directional locks, which only prevent the caster from pivoting. The choice depends on your specific needs—whether you need to lock the container in place or simply direct it in a straight line.

Size Matters: Selecting the Right Caster Dimensions

Let’s talk size—because it’s a big deal when it comes to casters. The right size ensures that the wheel can withstand the load without failing. But it’s not just about weight; it’s also about how the size affects maneuverability and clearance from the ground.

- Wheel Diameter: Larger wheels roll more easily over obstacles and rough surfaces, while smaller wheels are better for precision and lower load heights.

- Wheel Width: A wider wheel distributes weight more evenly, which can be crucial for heavy loads. However, they may require more force to start rolling.

- Overall Height: The height of the caster determines the clearance. This is important if you need to navigate over thresholds or uneven surfaces.

Choosing the right dimensions is a balancing act. You want a wheel that’s big enough to roll smoothly but not so large that it becomes unwieldy or raises the load too high.

When Diameter and Width Make a Difference

Diameter and width are two critical measurements that directly impact a caster’s performance. A larger diameter wheel will generally handle more weight and roll easier than a smaller one, but it will also raise the load higher off the ground, which may not always be desirable.

- If your floors are uneven or have debris, a larger diameter will help the caster navigate more easily.

- For heavy loads, a wider wheel will help distribute the weight more effectively, reducing the risk of indentation on softer floors.

Therefore, consider the environment and the nature of the loads when selecting caster dimensions. A little foresight here can save a lot of hassle down the line.

Custom Size Solutions for Unique Containers

One size does not fit all in the world of heavy-duty swivel casters. Sometimes, your containers might have specific requirements that off-the-shelf options can’t meet. That’s when custom-sized casters come into play.

Custom solutions ensure that every aspect of the caster, from the wheel material to the bearing type, is tailored to your needs. It might require a bit more upfront planning, but it pays off in performance and durability.

Keeping it Rolling: Maintenance Tips for Longevity

Like any piece of equipment, heavy-duty swivel casters require maintenance to keep them rolling smoothly. Neglect can lead to premature wear, operational inefficiencies, and even safety hazards.

Routine Care for Continuous Performance

Regular checks and basic maintenance can significantly extend the life of your casters. Here are a few tips:

- Keep the wheels clean to prevent debris from damaging the bearings.

- Regularly check for and tighten any loose bolts or fasteners.

- Lubricate the swivel bearings and wheel axles according to the manufacturer’s recommendations.

By keeping an eye on these key areas, you can ensure that your heavy-duty swivel casters continue to perform at their best for as long as possible.

Size, Load Capacity, and Wheel Type at a Glance

| Size (Diameter) | Load Capacity (per Caster) | Features |

|---|---|---|

| 6″ (152mm) | 6,000 lbs (2,722 kg) | Set of 4, swivel design |

| 8″ (203mm) | 6,600 lbs (2,994 kg) | Single wheel, polyurethane/nylon |

| 10″ (254mm) | 8,000 lbs (3,629 kg) | Heavy-duty nylon wheel, swivel lock |

| 12″ (305mm) | 8,000 lbs (3,629 kg) | Polyurethane tread, swivel lock |

| Custom sizes available | Up to 11,000 lbs (4,990 kg) | ISO corner fittings, brakes available |

References:

https://www.amazon.com/Container-Caster-Swivel-Wheels-Pack/dp/B01LYNVXVU

https://www.myteeproducts.com/shipping-container-caster-single-wheel-6600-lbs-wll.html

https://www.accesscasters.com/isocontainercasters.aspx

https://shipped.com/parts/containers/swivel-caster-wheel

Frequently Asked Questions (FAQ)

How do Heavy-Duty Casters Handle Varied Terrains?

Heavy-duty casters are designed to handle a range of terrains, but the key is in the wheel material and tread design. For instance, casters with pneumatic wheels are ideal for outdoor use where surfaces may be uneven or rough. They absorb shocks and provide a cushioned ride for the cargo.

For smoother indoor surfaces, polyurethane or nylon wheels might be the better choice, offering durability and floor protection. It’s all about matching the caster to the environment it will be used in. If you’re unsure, consult with the manufacturer about the best option for your specific terrain.

What Safety Precautions Should Be Taken with Swivel Casters?

Safety should always be a top priority when it comes to moving heavy loads. Here are some precautions to consider:

- Ensure that the load capacity of the casters exceeds the weight of the container and its contents.

- Regularly inspect casters for signs of wear or damage, such as cracks or flat spots on the wheels.

- Use locking mechanisms to secure the casters when loading or unloading containers to prevent unintended movement.

- Train your staff on proper handling techniques to avoid tipping or overloading the casters.

By following these guidelines, you can help prevent accidents and maintain a safe working environment.

Can Swivel Casters be Custom-Made for Specific Applications?

Yes, custom-made swivel casters are a possibility and often a necessity for specialized applications. Manufacturers can tailor casters to your exact specifications, including size, load capacity, wheel material, and bearing types. This customization ensures that your casters are perfectly suited to the demands of your unique operational environment.

When ordering custom casters, be prepared to provide detailed information about your requirements. The more precise you are, the better the manufacturer can meet your needs.

Are There Industry Standards for These Types of Casters?

There are industry standards for casters, including those set by the Institute of Caster and Wheel Manufacturers (ICWM) and the American National Standards Institute (ANSI). These standards cover aspects like performance, safety, and durability to ensure that casters meet a certain level of quality and reliability.

When purchasing casters, look for products that meet or exceed these standards to ensure you’re getting a product that’s been rigorously tested and proven to perform.

How Frequently Should Casters be Replaced or Serviced?

The frequency of replacement or service for casters depends on several factors, including usage, load size, and operating conditions. As a general rule, casters should be inspected regularly for signs of wear or damage. Any caster that shows significant wear should be replaced immediately to prevent failure.

As for servicing, it’s wise to establish a routine maintenance schedule based on the manufacturer’s recommendations. Regular lubrication and tightening of components can greatly extend the life of your casters.

In conclusion, heavy-duty swivel casters are a linchpin in the world of industrial material handling. They offer unmatched maneuverability and can significantly boost the efficiency of your shipping operations. By carefully selecting the right size, load capacity, and wheel type for your needs—and adhering to a proper maintenance schedule—you’ll ensure that your containers keep moving smoothly and your operations stay on track. Remember, in the industrial world, every move counts, and with the right set of wheels, you’ll be well on your way to optimizing your workflow.

Leave a Reply