Key Takeaways

- Maximizing space is crucial in shipping container kitchens; every inch counts.

- Modularity allows for future expansion and adaptability of your kitchen.

- Understanding and adhering to regulations will save time and money.

- Costs can be significantly lower than traditional builds, but planning is key.

- Shipping container kitchens offer unique benefits in sustainability and mobility.

Redefining Commercial Kitchens: The Shipping Container Revolution

Think of a commercial kitchen, and you might envision a vast, bustling space. But what if I told you that some of the most efficient, eco-friendly, and cost-effective kitchens are actually being crafted inside the humble confines of shipping containers? These compact powerhouses are changing the game for food entrepreneurs and culinary professionals everywhere.

Compact Efficiency: The Allure of Shipping Container Kitchens

Space is a premium, and in the world of shipping container kitchens, it’s all about making the most of what you’ve got. These kitchens force you to think critically about every square inch, ensuring that each component is there for a reason. But it’s not just about fitting things in; it’s about creating a workflow that allows chefs to move seamlessly from one task to the next.

And let’s not forget the green angle. By repurposing containers, you’re giving new life to what was once idle industrial waste. This not only cuts down on construction materials but also adds a unique story to your business.

My Favorite Container Homes Resource

I compared the top 3 Container Home Guides

to discover the ultimate resource!

See my top recommendation here

The Trend of Mobility: Shipping Container Kitchens on the Move

One of the most enticing aspects of a shipping container kitchen is its inherent mobility. Whether you’re catering to a festival crowd or setting up shop at a local market, the ability to move your business where the customers are is invaluable. This flexibility allows you to test different locations and markets with minimal risk.

Designing for Space and Functionality

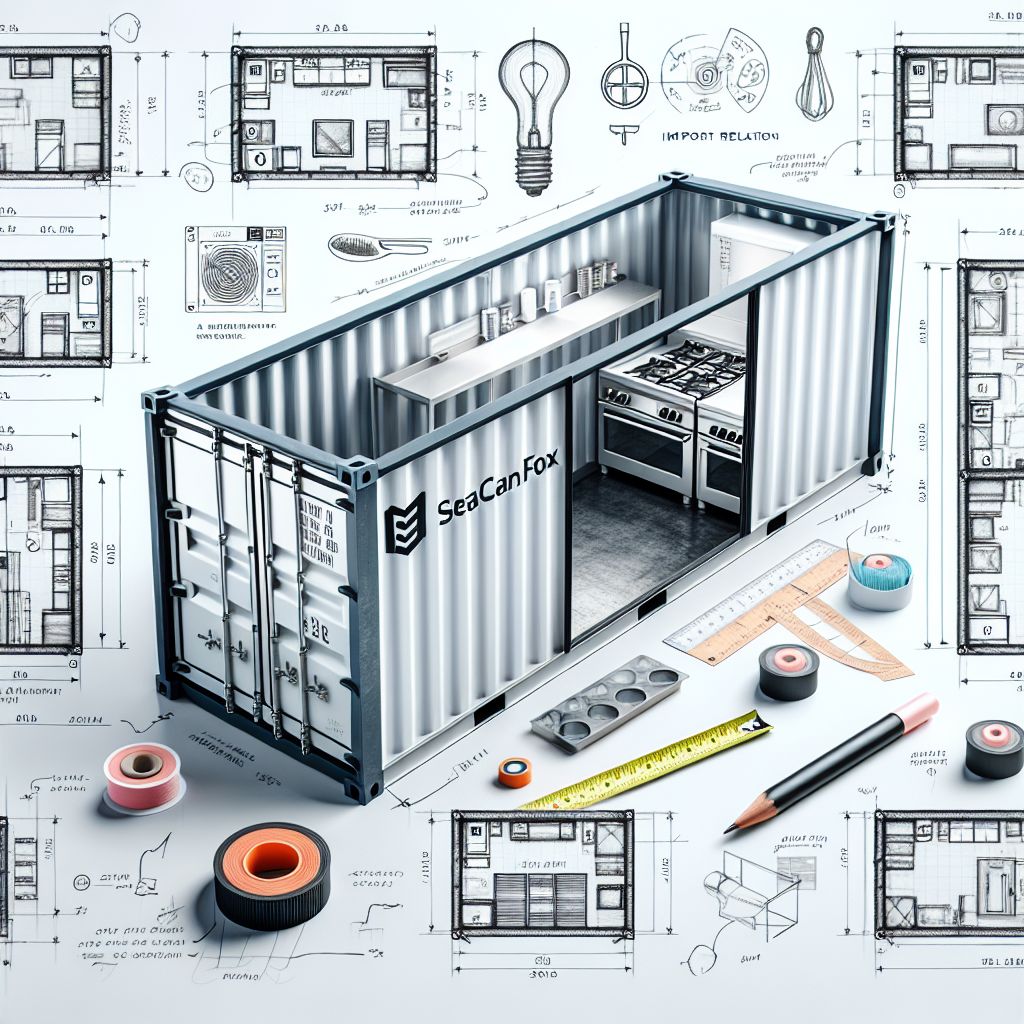

Blueprint for Success: Crafting the Layout

Designing a kitchen inside a shipping container is like solving a puzzle. Every piece must fit perfectly. Start with the essentials – cooking equipment, refrigeration, and sanitation stations – and then build out from there. A well-thought-out design balances the need for storage with the working space required for food prep. For those considering this innovative approach, exploring custom shipping container kitchens can provide valuable insights into maximizing efficiency and functionality.

Getting the Size Right: Fitting a Kitchen in a Container

Choosing the right container size is your first step. Standard containers come in 20-foot and 40-foot lengths, but they can also be customized. For a small café or a food truck alternative, a 20-foot container might suffice. However, if you’re looking to operate a full-scale restaurant, you’ll likely need the larger option or even consider joining multiple containers.

Smart Storage Solutions: Making Every Inch Count

Smart storage is not just a buzzword; it’s a necessity. Utilize vertical space with shelving and hanging racks. Consider fold-down prep areas that can be tucked away when not in use. And remember, the right storage solutions not only save space but also reduce clutter and increase efficiency.

Most importantly, everything should have its place. This not only saves space but also creates a safer working environment and a more efficient kitchen.

Scaling Up: Modular Options for Expansion

One of the most significant advantages of shipping container kitchens is their modularity. As your business grows, so too can your kitchen. By designing with expansion in mind, you can add new sections or even stack containers to create a multi-level culinary complex.

Cost Considerations: Setting a Budget

Expense Essentials: What To Expect

When budgeting for your shipping container kitchen, it’s essential to consider not just the cost of the container itself, but also the modifications needed. On average, a basic fit-out for a 20-foot container kitchen can start from around $20,000, while more extensive modifications and equipment can push the price upwards of $50,000.

Cost Comparisons: Shipping Container vs. Traditional Builds

Comparing the cost of a shipping container kitchen to a traditional build is like night and day. Traditional builds can easily run into the hundreds of thousands, whereas a container kitchen often costs a fraction of that. But remember, the key to keeping costs down is efficient planning and design.

Rules of the Game: Navigating Regulations

Starting with Legality: Permits and Zoning

Before you get too far into the weeds with your design, it’s critical to understand the legal landscape. Depending on your location, permits and zoning laws can vary significantly. Reach out to your local planning department early on to avoid any costly surprises down the line.

Health and Safety: Meeting Commercial Kitchen Standards

Health and safety regulations are non-negotiable. Your container kitchen will need to meet the same standards as any traditional kitchen. This means proper ventilation, fire suppression systems, and food safety protocols must be in place. Doing this right the first time will save you from headaches later.

Stay tuned for the next segment, where we’ll dive into the specifics of turnaround times, the approval process, and a detailed comparison of your options.

Turnaround Times: From Concept to Reality

When you’re fired up about launching your container kitchen, understanding the timeline from concept to reality is essential. It’s not just about speed; it’s about meticulous planning and execution. A standard shipping container kitchen can take anywhere from a few weeks to several months to complete, depending on the complexity of your design and the specifics of your build.

Timeline Targets: Estimating Build Time

As you map out your project, set realistic timeline targets. For a basic setup, you might be looking at 8-12 weeks, but if you’re going for a more customized kitchen with high-end finishes, expect the timeline to extend. It’s crucial to factor in time for design approval, material delivery, and construction.

Speedy Setup: Tips for Efficient Construction

To keep your project on track, focus on efficiency. This means having a clear design from the get-go, choosing prefabricated elements where possible, and working with contractors who have experience in shipping container modifications. Besides that, ensure you have all materials and equipment ordered and ready to avoid delays.

Approval Processes: Staying Compliant

Every successful shipping container kitchen starts with a green light from the authorities. Get to know your local health department and fire marshal. They are your allies in ensuring your kitchen meets all the necessary codes and regulations.

Now, the approval process can seem daunting, but it’s all about preparation. Make sure your plans address every detail, from electrical wiring to plumbing. This level of precision will make the inspection process smoother.

Inspection Insights: Preparing for Health and Fire Safety

Inspections are a critical part of the approval process. You’ll need to pass health inspections, which focus on food safety, and fire safety inspections, which ensure your kitchen has the proper suppression systems and exits. Schedule mock inspections to identify any issues before the official ones.

Documentation Demystified: What Paperwork You Need

Gathering the right documentation is as important as the build itself. You’ll need detailed plans for your kitchen, proof of ownership for the container, and any permits required by your municipality. Keep a well-organized file with all these documents, as you’ll need to present them at various stages of the approval process.

Comparing Your Options: A Detailed Look

When it comes to shipping container kitchens, there are several paths you can take. You might opt for a do-it-yourself approach, hiring out individual contractors for each phase of the build. Alternatively, you could work with a company that specializes in container modifications, offering a one-stop-shop solution.

Size Comparisons: When Less Is More

When choosing the size of your container, consider the scope of your operation. A smaller container might be all you need for a boutique café or a pop-up event kitchen, and it can be more cost-effective and easier to place in tight spaces.

Build Time Comparisons: The Race to Opening Day

DIY builds can take longer, as you’re coordinating multiple contractors and possibly learning as you go. A professional company, on the other hand, can streamline the process, potentially getting your kitchen up and running in less time.

Approval Comparisons: Smoother Sailing Through Red Tape

Professional builders are often more familiar with the regulatory landscape, which can mean a smoother approval process. They know what inspectors are looking for and can help ensure your kitchen design ticks all the boxes from the start.

Shipping Container Kitchen: Pros and Cons

Shipping container kitchens are not a one-size-fits-all solution. They come with a unique set of benefits and challenges that you need to weigh before diving in.

The Benefits: Flexibility, Cost, and Sustainability

The benefits of shipping container kitchens are clear: they’re flexible, allowing you to move your business as needed; they’re cost-effective, often coming in at a lower price point than traditional builds; and they’re sustainable, repurposing existing materials for a new use.

The Challenges: Spatial Constraints and Local Ordinances

However, there are challenges too. Spatial constraints mean you have to be smart about your design to ensure you’re using every inch wisely. Local ordinances can also vary greatly, and what’s permissible in one area may not be in another. Research and preparation are key.

Commercial Kitchen Design Considerations Summary:

| Design Principle | Regulatory Consideration | Efficient Planning |

|---|---|---|

| Workflow Optimization 4 | Permits and Approvals 3 | Consult Experts 1, 2, 3 |

| Open and Communicative 4 | Health and Safety 4, 5 | Consider Kitchen Type 1, 3 |

| Flexibility and Mobility 4 | Utilities 3 | Prioritize Essential Equipment 4 |

| Maximize Space 2, 5 | Modular and Scalable 2, 3 | |

| Comfort and Safety 5 |

Comparison Table

Let’s put things into perspective with a comparison table. This visual tool can help you weigh the pros and cons, understand the costs, and get a clearer picture of what it takes to bring a shipping container kitchen to life.

| Feature | Shipping Container Kitchen | Traditional Kitchen Build |

|---|---|---|

| Cost | $20,000 – $50,000 | $100,000+ |

| Build Time | 8-12 weeks | 6 months+ |

| Sustainability | High (repurposed materials) | Varies |

| Flexibility | Mobile and expandable | Fixed location |

| Regulatory Navigation | Depends on builder expertise | Requires extensive knowledge |

As you can see, shipping container kitchens offer a distinct set of advantages, particularly in cost and flexibility. But, they also demand a level of creativity and due diligence to ensure they meet all necessary standards and fit your specific needs.

Shipping container kitchens are an innovative solution that cater to the modern culinary professional’s needs for flexibility, cost-efficiency, and sustainability. Whether you’re starting a new venture or expanding an existing one, the possibilities are as limitless as your creativity. Remember, the key to success lies in meticulous planning, understanding regulations, and designing a space that maximizes efficiency. With these insights, you’re well on your way to making your mark in the food industry with a shipping container kitchen that stands out from the crowd.

Frequently Asked Questions (FAQ)

What Are the Initial Steps to Designing a Shipping Container Kitchen?

The initial steps involve thorough planning and research. Begin by defining your concept and menu, as this will dictate the equipment and layout you’ll need. Next, consult with experts to ensure your design complies with local regulations and health codes. Then, consider the size and type of container that best suits your needs. Finally, start sketching out a floor plan, keeping in mind the importance of an efficient workflow.

How Do I Determine the Right Size for My Shipping Container Kitchen?

To determine the right size, assess the scale of your operation and the amount of equipment you’ll need. A 20-foot container might be sufficient for a small café or pop-up, while a 40-foot container could be more appropriate for a full-service restaurant. Remember, you can always start small and expand later thanks to the modular nature of shipping containers.

What Are the Most Common Pitfalls When Planning a Shipping Container Kitchen?

The most common pitfalls include underestimating the importance of a well-designed layout, neglecting local regulations and health codes, and overlooking the need for high-quality ventilation systems. Additionally, failing to plan for adequate storage and prep space can lead to operational inefficiencies.

Can Shipping Container Kitchens Be Expanded or Repurposed?

Absolutely! One of the most appealing aspects of shipping container kitchens is their modularity. You can add new sections, stack containers for additional space, or repurpose them for different uses as your business evolves. This flexibility is a significant advantage over traditional brick-and-mortar structures.

What Are Some Unique Design Features Seen in Shipping Container Kitchens?

Unique design features in shipping container kitchens often include foldable counters, retractable windows or walls for open-air dining, rooftop gardens, and smart storage solutions like magnetic spice racks and ceiling-mounted pot holders. These features not only save space but also add character and functionality to the kitchen.